Introduction

Begin with context: In modern industrial and power distribution systems, maintaining insulation integrity is critical to safety and system reliability. A fault in insulation can cause earth leakage, unexpected tripping, downtime, or even hazards. The ABB CM-IWN-AC insulation / monitoring relay helps detect insulation drop and warns or isolates faults before damage occurs.

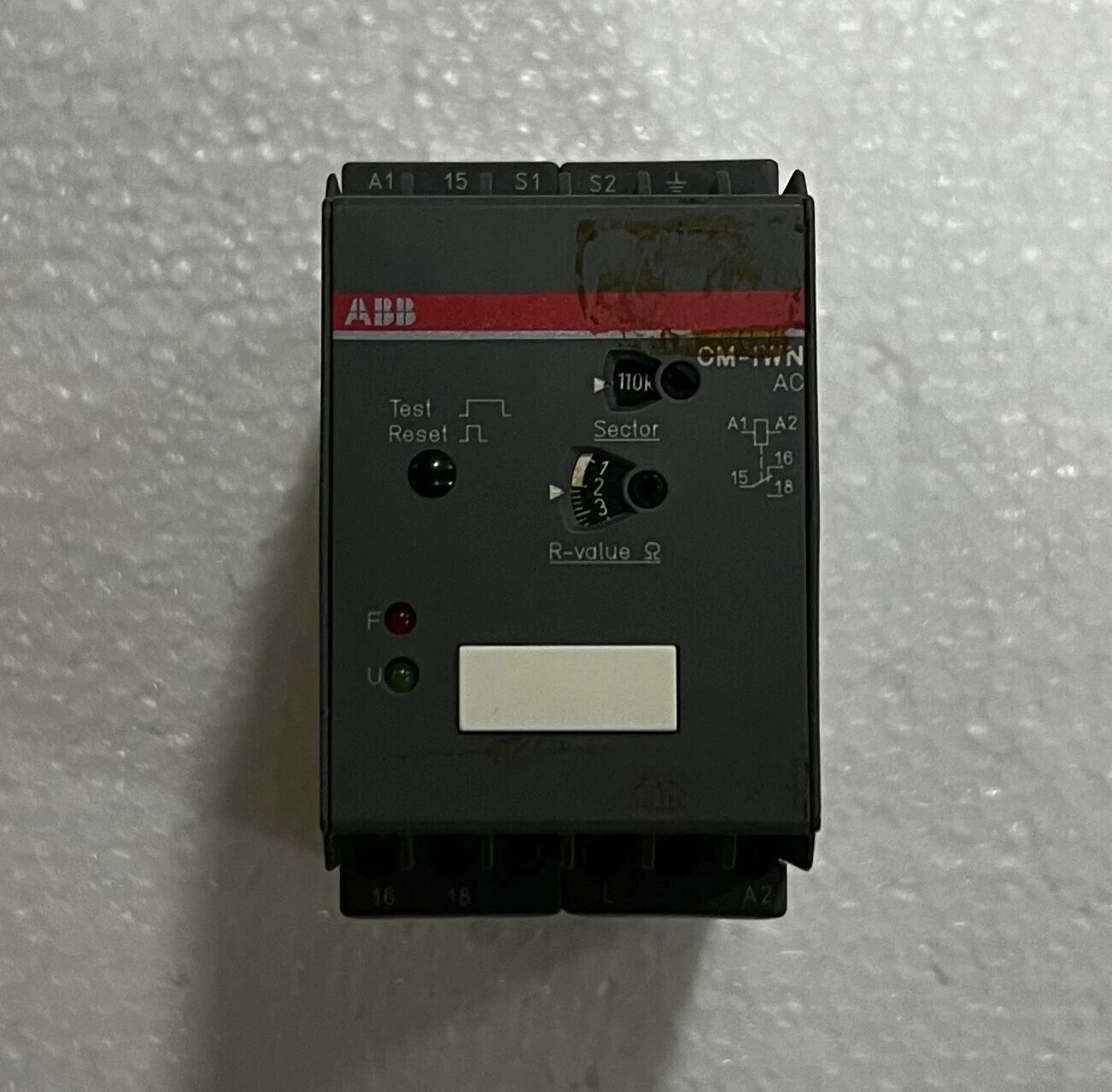

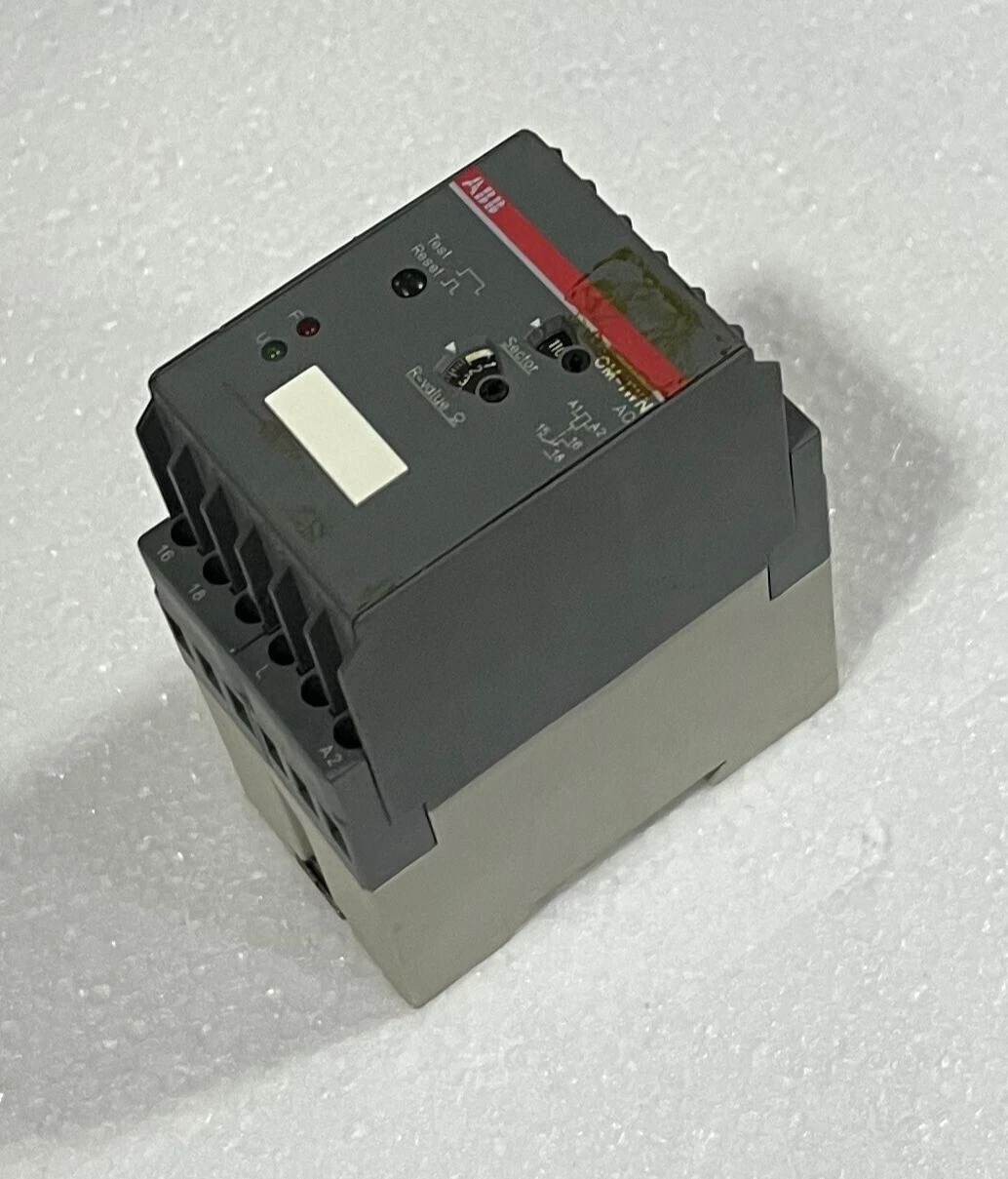

What Is the ABB CM-IWN-AC Monitoring Relay?

It is an insulation/monitoring relay (sometimes also called insulation resistance relay) designed to monitor the insulation resistance between active circuits and earth in unearthed (IT) systems or isolated AC/DC circuits.

It has a supply (control/coil) voltage range of 24–240 V AC/DC.

It provides 1 C/O (SPDT) contact output.

It is / was sold under the ABB / ASEA Brown Boveri brand, though some listings indicate it is discontinued.

On listings, it is described with parameters like sensitivity (L–PE: 1–110 kΩ), maximum AC voltage rating, etc.

Technical Specifications

Here’s a more detailed spec summary you can insert (you may verify with datasheet or ABB’s official documentation):

You can also include diagrams (if you have datasheet) showing wiring, terminals (A1/A2, L+, L–, KE, etc.).

Key Features & Benefits

Early Fault Detection: It signals insulation resistance falling below threshold before catastrophic faults.

Configurable thresholds: You can adjust the setpoint (prewarning, final trip) to suit system design.

Wire break detection: Detects disconnection in sensing circuits.

Fault memory: Keeps record of insulation events for diagnostics.

Compact design: Fits into control panels or DIN rail assemblies.

Wide supply voltage range (24–240 V) gives flexibility in system design.

High reliability: Built to industrial standards and approvals (IEC / EN).

Typical Applications

IT power systems / unearthed systems: Common in hospitals, data centers, critical installations where continuity must be maintained even with a first earth fault.

Renewable energy systems (inverters, battery installations) where leakage must be monitored.

Marine and offshore installations for insulation monitoring aboard ships or rigs.

Control / automation panels where leakage or insulation degradation must trigger alarms or isolation.

Industrial machines / drives where insulation health is vital for safety and uptime.

Challenges, Limitations & Considerations

Because many listings mark it discontinued or “currently unavailable” (e.g. RS listing) , inventory and spare availability is a concern.

For higher voltages beyond the direct range, coupling or extension modules may be needed.

Settings must be correct (thresholds, hysteresis, wiring) — misconfiguration may lead to nuisance tripping or missed faults.

Sensitivity vs system leakage capacitance trade-offs: in large capacitance systems, the relay must be tuned properly.

While listings show “used / surplus” stock, you should ensure testing, calibration, warranty before deploying.

Buying Guide & Tips

Always verify genuine part number (1SVR450075R0000) and match with datasheet.

Request calibration certificates or testing reports, especially for secondhand or surplus units.

Ensure compatibility with system leakage capacitance, voltages, wiring layout.

Ask about warranty / return policy if buying used / refurbished.

Consider alternative or newer models if the product is discontinued

Use correct installation practices: proper earthing, shielding, correct terminal connections, avoiding interference.

Dutch Marine Supply | |||

We also offer consultancy on selecting the right insulation / monitoring relay for your IT systems.